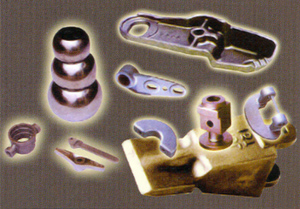

Investment Casting

ABT produces custom designed castings for industrial use according to ASME, ASTM and

ISO standards. With advanced technology, rich experience, and mass production capability, we are

able to offer cost-effective castings of the highest quality.

Investment Casting Process

Castings are produced by surrounding or investing an expendable pattern (Wax, Sodium Silicate,

Silica Sol, etc) with a refractory slurry coating. The pattern is removed through the use of heat prior

to filling the mold with liquid metal. ABT integrates product and mold design, mass production

and after-cast precision machining.

Advantages

Investment Castings have several advantages over other manufacturing processes.

• Extensive range of raw materials

• Complicated structure

• Good surface finish

• Tight tolerance

Cast Material

Carbon, Tool, Alloy, Stainless Steel, and non-ferrous steel such as Aluminum, Copper base, etc.

Typical Size Range

oz. - 100 lbs (1000 lbs max.)

Dimensional Tolerance

±.003" (as cast)

Surface Roughness

63-125 RMS (as cast)

Surface Finish

• Polishing

• Rust protective oil or paint

• Plating (zinc, chrome, etc)

• Anodizing

Services

• Product and mold design

• Mold making

• Casting

• Heat treatment, Machining, Polishing, Coating, Assembly

• Testing & Quality Control

Applications

• Provides Spacer, Hangers, and Handcuffs

• Mining and road machines

• Valves and Piping parts

• Petroleum, shipping, and railroad industries

• Automobile and motorcycle parts

• Mechanical and Electrical parts, Hardware

• Industrial and Agricultural machinery parts

|